Fill & Finish lines

Designs, develops, and manufactures washing, sterilizing, filling, and closing machines for vials, ampoules, bottles, cartridges, syringes, 3 piece and IV Bags to process liquid and powders for sterile, non-sterile, diagnostic and nuclear medicine applications. The machines run either individually or can be integrated into a complete production line or can be Combi lines.

Detail View

INSPECTION MACHINES

PBL offers innovative and flexible custom designed inspection machine for all types of containers. by means of cameras supported by Artificial Intelligence, could inspect different types of containers such as vials, PP/PE bottles, syringes, cartridges and IV bags with the integration of a fully automatic format changeover, in order to remove any operator intervention.

Detail View

Leak Testing (CCIT)

PBL offers an innovative and flexible leak testing machine for all types of containers. The main objective was to create a machine capable of performing leak tests using a vacuum decay (VD) system or High voltage (HV) system, with high performance in terms of efficiency and detection of small micro-holes supported by Artificial Intelligence, could inspect different types of containers such as vials, PP/PE bottles, syringes, cartridges and IV bags.

Detail View

CELL & GENE FACTORY ATMPS

PBL Pharma division has design a customizable and highly innovative isolator able to completely automate different ATMPs production processes, which are, up to now, only manually performed by research institutes and pharmaceutical workshops. The 100% class A system, completely sterilizable through VHP (or similar), can be provided with loading cells with weight and dosing control, centrifuge, incubation systems, microscope, environmental monitoring, robotic handling and visual inspection. The high flexibility allows to reproduce the production steps required for ATMPs. It is possible to easily modify the process steps and/or to insert tools and instrumentations for cellular selection, electroporation, activation, viral transduction, expansion and formulation.

Detail View

MICRO ASEPTIC UNSCRAMBLER

MICRO ASEPTIC unscrambler, ideal for automation solutions for your line in the pharmaceutical industry, offers higher yields in positioning, compared to other systems, reaching production speeds of up to 120 units/min with a single unit.

Detail View

THE STERAPAK

Experience SteraMist iHP technology in the most portable decontamination system yet. Part of the SteraMist line of multi surface disinfectant applications, the all-in-one SteraMist SteraPak delivers innovative disinfection that utilizes a rechargeable battery, cordless operation, and a compact BIT bottle. It is the ultimate versatile solution!

Detail View

THE SURFACE UNIT

Elevate your sterilization process from a time-consuming chore to a swift and efficient breeze with the SteraMist Surface Unit. Seamlessly integrating into existing processes and services, this cutting-edge device harnesses the power of iHP technology for rapid and flexible disinfection.

Detail View

ENVIRONMENT SYSTEM

When health and safety are paramount, the SteraMist Environment System delivers the promise of a completely disinfected environment. With patented iHP disinfection and decontamination technology, this system is setting a new standard in infection control and environmental health.

Detail View

STERAMIST INTEGRATED SYSTEM

Looking to integrate high-log decontamination that lets you comply with GMP, cGMP, GLP, and ISO standards without damaging your equipment or complicating protocols? Seamlessly incorporate SteraMist iHP decontamination technology into your enclosures.

Detail View

CUSTOM ENGINEERED SYSTEM

Built to meet the exacting standards of healthcare, biotech, cleanrooms, and other critical environments; SteraMist Custom Engineered System (CES) is designed to cater to your specific disinfection requirements—delivering unmatched decontamination efficacy where it matters most.

Detail View

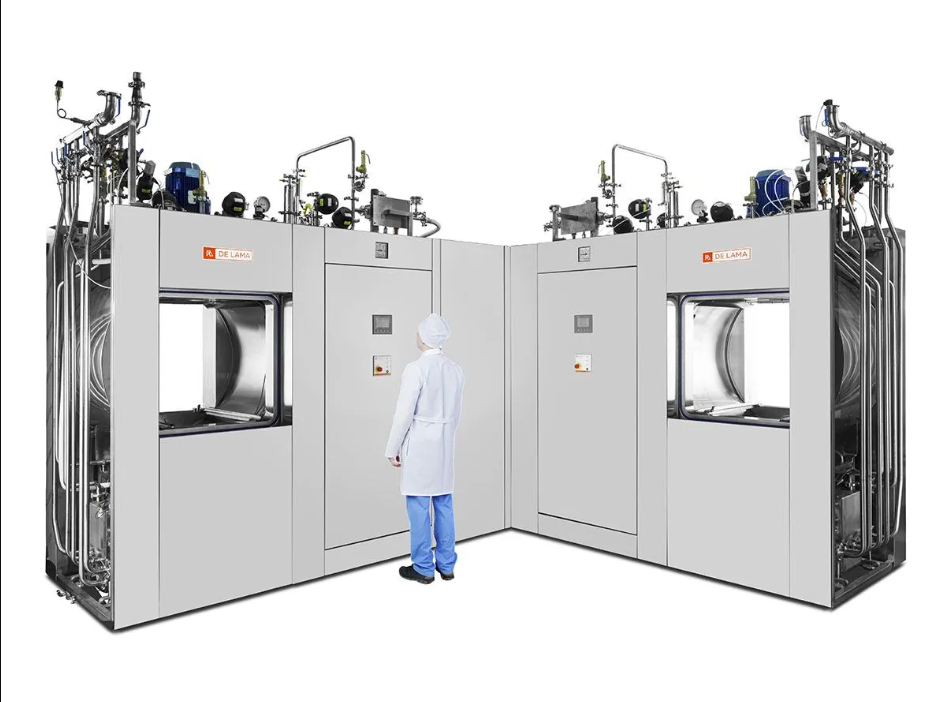

Sterilizers

De Lama Manufactured Saturated steam sterilizer, Air/steam mixture sterilizer, Superheated water sterilizers. Ethylene oxide sterilizers, DHS - Dry Heat Ovens For Sterilization And Depyrogenation Class, H2O2 Sterilizer in high vacuum and zero air with HyPerPure® technology, Saturated steam sterilizer for Biohazardous materials (BSL3 and BSL4)

Detail View

Washers

The new De Lama washer, is the result of over 20 years of experience in industrial washing machines for the pharmaceutical sector.

Detail View

PASSBOXES FOR DECONTAMINATION

De Lama’s new line of Vaporized Hydrogen Peroxide pass-boxes for decontamination achieves the highest technology standards in the industry, including a series of innovations that take this product to another level. The pass-box works with vaporized hydrogen peroxide and offers the possibility of total customization, in particular of the size and shape to adapt to the available spaces of the customer and the loads that must be carried out.

Detail View